When you need to install a raised walkway without the use of permanent, fixed structures, where do you find the right solution?

Yarra Valley Water (YVW) came across this exact problem during the recent upgrade to its Brushy Creek Sewage Treatment Plant (STP), specifically in the chemical dosing facility. Because the Plant deals with aluminium sulphate and sodium hydroxide – both of which are corrosive chemicals – the floor in the sump around the chemical tanks is constructed with a chemical-proof membrane.

The challenge with this flooring? YVW needed to build a walkway over it but there couldn’t be any damage or perforations made to the membrane. A particularly difficult situation when most walkways require screws and bolts to secure them.

Already familiar with the benefits of fibre reinforced plastic (FRP), YVW specifically requested FRP grating for the walkway, but it was up to Terra Firma Industries to figure out exactly how to set this walkway up to protect the facilitys’ floors.

Treated flooring throws a spanner in the works

The treated flooring of the STP presented quite a challenge to build a raised walkway on due to its unique purpose, as well as the location and nature of the facility. The limitations of the project included:

- No fixed structures – no bolts or screws could be used on the specialty waterproof membrane of the floor that’s used to contain chemical spills – any damage to it would be costly and would render it useless

- Corrosive chemicals and fire risks – with the possibility of chemical spills and potential bushfires, the platform needed to withstand both of these events

- A complex floorplan – the facility has multiple pipes and storage tanks that required the flooring to be cut to fit – but because Brushy Creek is a bushfire zone, the flooring couldn’t be welded or worked on in a way that could send sparks into the air on-site and risk creating a fire

- Future works planned – the facility would most likely have further works done on it in the future, and the flooring system had to be flexible to allow workers to reach every part of the facility during repairs or routine maintenance.

- Safety and environmental risks – the raised flooring system had to provide adequate drainage capacity for the rapid containment of any spills to project workers and the surrounding environment from hazardous chemicals -whilst providing the required load bearing capacity to meet with AS/NZ walkway standards.

Adjustable pedestals are the clear winner in protecting treated floors

It was crucial for Yarra Valley Water to have a way to install a raised walkway without the need for bolts or screws.

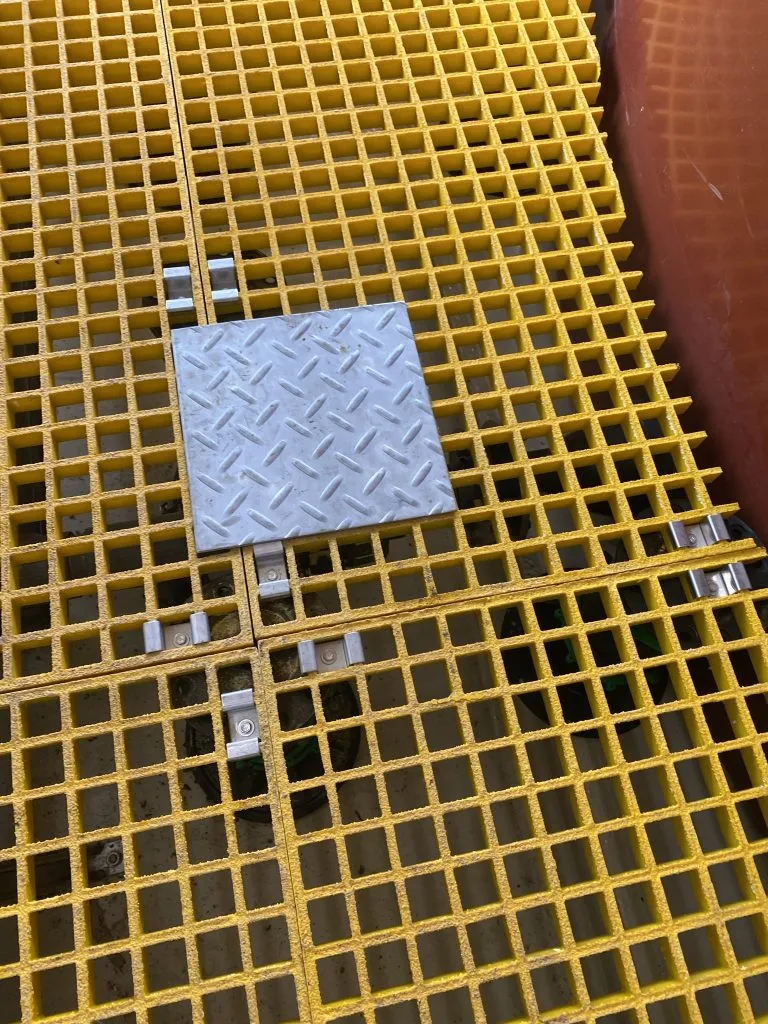

And it was this challenge that Terra Firma had the perfect solution for: adjustable self-supporting pedestals. These pedestals would have the FRP mesh walkway attached, so no structural members would be needed anywhere in the solution.

After analysing the chemical resistance requirements of the project, Terra Firma provided the TerraGrate self-supporting FRP flooring system that incorporated a range of specialist Vinyl Esther resins which would meet the anti-corrosive and anti-flammable requirements. While FRP is naturally fire-resistant, the inclusion of Vinyl Esther dialled this up even further.

The specific products supplied were:

- TerraGrate Adjustable Pedestals – these are self-supporting and interlocking pedestals with non-penetrative fixings, and can be adjusted or moved to allow workers to access underneath them

- TerraGrate FRP moulded grating – this mesh attaches to the pedestals and is available in a variety of resins, standard and custom colours, depths, panel sizes and mesh configurations

No downsides to FRP for treated and specialty floors

For water authorities, the many benefits of the FRP pedestals and flooring are evident in their:

- Flexibility and accessibility – the flooring and pedestals can be unclipped in individual sections, thus leaving other parts of the walkway still accessible and free to use by work personnel

- Safety – with materials that don’t require on-site welding or heavy lifting, the personnel at the facility have fewer hazards and risks at work – a benefit to both employer and employees

- Quick and easy installation – the lightweight flooring was quick, safe, and easy to cut and install, requiring only two people to do so. Without other project delays, this work can be done in a week

- Longer lifespan – FRP grating that’s anti-corrosive and anti-flammable will last longer than its metal counterparts, and the flooring system in Brushy Creek is predicted to last the entire lifespan of the facility (25-30 years)

Innovative flooring solutions in FRP pedestals and grating

FRP demand is growing thanks to the flexibility it provides for flooring solutions, which makes this is the perfect time to invest in these materials for your next project. If you’re keen to learn more about this project, you can watch our video showcasing the flooring solution for Brushy Creek here.

Terra Firma Industries is Australia’s leading manufacturer and supplier of FRP grating. Proudly Australian-owned and locally designed and fabricated, our products make the best use of cutting-edge technologies and leading R&D.

If you’d like to know how composite materials could benefit your next project, you can contact us here to discuss it.

Share this

Discover the Terra

Firma difference

Learn how we can help support your next project