Boardwalks are often the heart of a local park — places where families walk, anglers gather, and communities unwind. But behind the calm scenery is a difficult truth: timber doesn’t age gently, especially around water.

At Queens Park Lake, that challenge had become impossible to ignore.

Why Traditional Timber Boardwalks Struggle

Water, weather, and foot traffic are a tough combination. Over time, timber absorbs moisture, swells, and breaks down. Boards loosen. Surfaces become slippery. Regular patch-ups turn into major repairs.

For councils and community asset managers, this creates a familiar cycle:

- Safety concerns after rain or frost

- Frequent inspections and spot repairs

- Escalating maintenance budgets

- Disruptions to public access

It’s a cycle many regional councils are now looking to break — and Queens Park Lake is a perfect example of what a long-term solution can look like.

The Challenge at Queens Park Lake

The existing timber boardwalk around the lake had reached the point where repairs were no longer enough. Community use hadn’t slowed down, but the structure’s condition had.

The council needed a replacement that could handle:

- Constant exposure to water and humidity

- High foot traffic from daily park users

- Minimal disruption to a popular public space

- Better long-term safety (especially non-slip performance)

- Lower lifecycle cost than timber

They weren’t just after a “new boardwalk.”

They were looking for a boardwalk that wouldn’t need rebuilding again in 10–15 years.

The FRP Solution: A Boardwalk Built for the Long Term

FRP (Fibre Reinforced Plastic) offered exactly what the site needed: durability, safety, and real lifecycle value.

1. Long-term safety, even in wet environments

FRP’s integrated non-slip surface provides consistent grip — unlike timber, which becomes slick when damp or worn.

For Queens Park Lake, this meant safer access year-round, with far fewer slip risks during wet weather.

2. No rot, no corrosion, no costly upkeep

Where timber absorbs moisture and breaks down, FRP simply doesn’t.

It doesn’t rot, warp, or corrode — which means no repainting, no sealing, and minimal ongoing attention from maintenance crews.

3. Quick installation with minimal community disruption

Because FRP is lightweight and prefabricated, installation teams were able to work efficiently onsite.

For parks, this means shorter closures, fewer detours, and happier community members.

4. Big savings across the boardwalk’s lifecycle

While timber may appear affordable up front, the long-game tells a different story.

Councils often spend far more on:

- repeated timber patching

- surface treatments

- safety inspections

- partial rebuilds

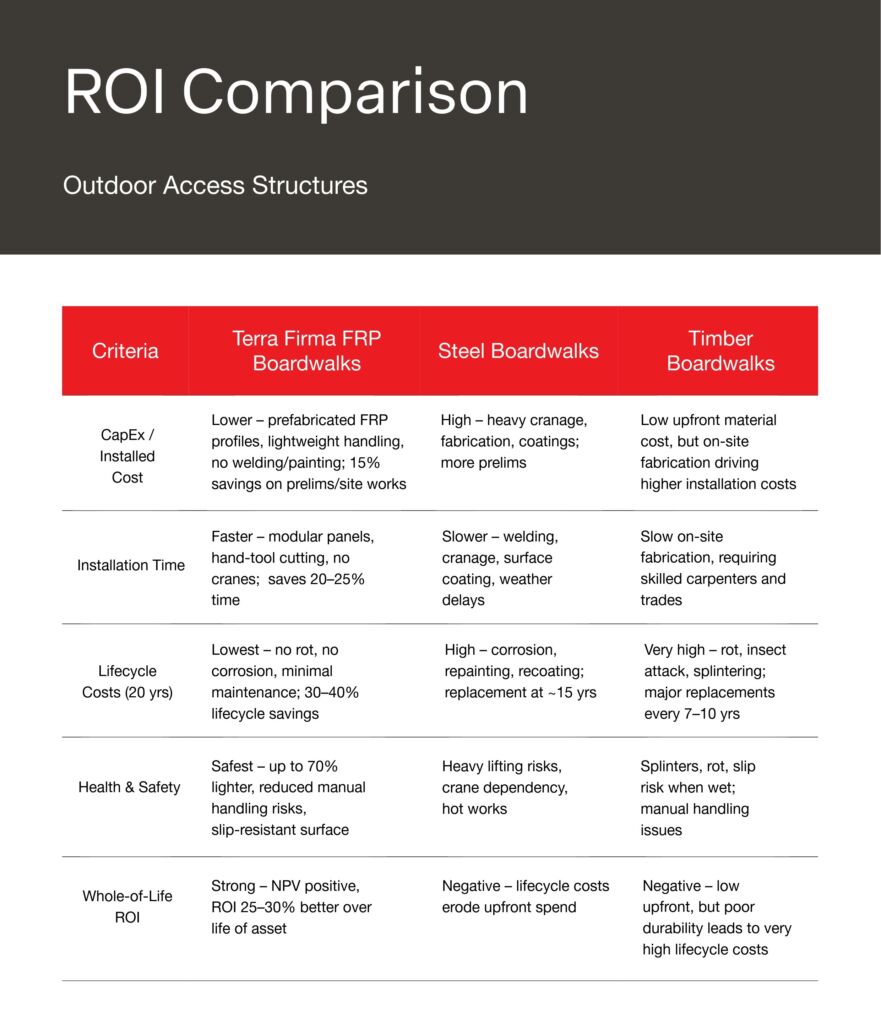

ROI analysis shows 30-40% savings over the boardwalks lifecycle. FRP shifts the cost profile from constant upkeep to true long-term asset performance — a major win for ratepayers and asset managers alike.

What This Upgrade Means for the Community

The Queens Park Lake upgrade wasn’t just an infrastructure improvement — it restored the walkway to something that feels safe, stable, and enjoyable again.

Visitors now have a boardwalk that:

- feels secure underfoot

- looks clean and modern

- is built to last for decades, not years

- will remain open and accessible without frequent maintenance shutdowns

That’s a better experience for everyone.

View the project case study (PDF)

Smarter Outdoor Access Starts With Better Materials

Projects like Queens Park Lake show how modern materials can reshape community spaces — making them safer, more sustainable, and more cost-effective over the long term.

If you’re planning a boardwalk, platform, or access upgrade, FRP could be the difference between a structure that lasts and one that needs constant attention.

Share this

Discover the Terra

Firma difference

Learn how we can help support your next project