Conventionally made from cast iron for over 300 years, manhole covers – as they were once called – could weigh up to 200 kilograms. Anchored by weight alone, their distinctive round design allowed users to roll them into place where needed. A prosaic and mundane necessity, they have played an important role in civil works projects for centuries, protecting a world of pipes, wires, conduits and drainage systems below our walkways, driveways, roads, freeways, docks, wharfs and runways, while providing convenient access for maintenance workers. As technology and community expectations and needs have grown, the humble access cover has until recently struggled to evolve.

Access covers are designated by classes from A through to G according to load capacity with the ‘typical use for class A’ for areas accessible strictly by pedestrians and with an ‘ultimate limit of 10 kN. At the heavy industrial end of the spectrum is Class G which is used in ‘docks, wharfs and airway runways’ and which allows a nominal wheel loading of 30,000 kg and an ultimate limit of 900 kN.

The relevant Australian Standard for Access Covers and Grates is AS 3996. Its original title – ‘Metal access covers, road grates and frames’ – echoed legacy materials, with subsequent revisions allowing aluminium and concrete to be added to the list of acceptable metals. The 2006 version of the standard made no specific reference to composite or polymeric products and only required a static load test for compliance, all of which stymied the development of the market for composite materials.

To compensate, Ashley Reid, Managing Director of the Melbourne based Access Cover and Pit Lid specialist firm Terra Firma Industries (TFI), had earlier adopted the requirements of the European standard EN124- 2015, which included a specific composites section (Part 5) and relevant materials testing for load, creep, high temperature, fatigue, UV and impact. But this was less than ideal.

Terra Firma D-240 Critical Access Road installation.

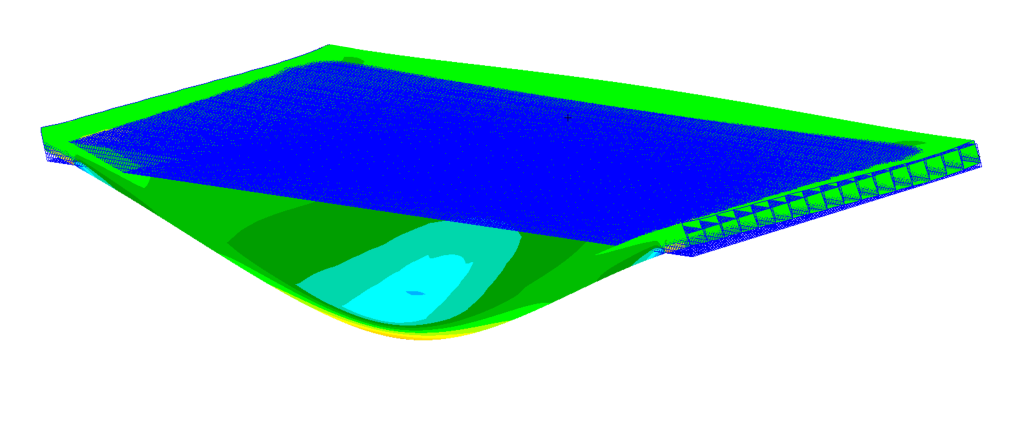

In 2018, Terra Firma partnered with Advanced Composite Structures Australia (ACS Australia), specialists in the design, analysis and manufacture of composite products, to develop the D240 Trench Cover. This was supported by the Victoria Government Advanced Manufacturing Voucher program. A lightweight pultruded composite panel was developed for the D240 Trench Cover which is rated to handle loads of 240 kN (~24 tons), suitable for trucks and other heavy vehicles. The design was successfully verified using Finite Element Analysis (FEA) simulation, and subsequent physical testing confirmed the trench covers passed AS3996 static strength and deflection testing for Class D criteria. Additional impact, durability, UV resistance, high temperature and sustained load testing was carried out to ensure the product was fit for purpose and could meet required performance standards. The pultruded composite design balances the requirement to be easily handled by maintenance personnel whilst still performing well within the limits of the standards.

Composite access cover – maximum strain at ultimate load.

After an announcement was made in 2018 to update the standard by Committee CE029 – the Australian Standards Committee responsible for AS 3996, and on which Composites Australia lobbied to become a member – TFI and Composites Australia stepped up their efforts to provide a voice for composites materials. Committee CE029 was made up of 12 representatives from 12 entities, most of which were resistant to new materials without the benefit of decades of data. “The committee was initially reticent to allow for composite covers. It then relented partly to allow composites for pedestrian applications. Eventually our evidence persuaded them to include composite or polymeric covers in the standard up to road covers rated to Class D. Testing regimes similar to EN124-5 were included although they mostly required higher levels of testing (e.g. Cyclic Load test EN124-5 100,000 cycles versus AS3996-2019 300,000 cycles),” recalled Ashley.

“Our collaborative efforts are paying off, with composite access covers being taken up by major utility providers including Jemena, the Australian company that owns, manages or operates energy infrastructure assets in the eastern states of Australia, along with its delivery and maintenance service partner, Zinfra.” – Ashley Reid

The committee ultimately agreed on the premise that there was a case for recognising ‘a natural transition of products from the previous version of the standards,’ and the revised and updated Australian Standard (AS3996) was published in March 2019 recognising composite materials in classes A up to D.

The transition, away from legacy materials began with trial retrofit installations at two existing zone substations using TFI’s AS3996-2019 compliant D240 cable pit lids and trench covers which are designed with a Safe Working Load of 8,000 kilograms. Key considerations for installing the D-240 Trench Covers included the requirements to be produced and installed quickly to allow for the crane truck delivery of critical plant and equipment; easy access for the laying and connection of cables once a control room had been installed; and durability under ongoing construction traffic.

Working closely with Jemena’s plant engineering team, TFI developed a labelling standard for each cover with safe workloads (SWLs) in addition to AS3996 Class loads for ease of recognition by maintenance operatives. Major utility providers are making the switch to composite materials for their projects because they’re finding them to be safer, more durable, and easier to operate.

Terra Firma acknowledges that this article was written by Kerryn Caulfield, Executive Director at Composites Australia. Access the article here.

Share this

Discover the Terra

Firma difference

Learn how we can help support your next project