Australia’s civil construction landscape continues to focus on improving safety standards. Building guidelines are regularly updated and standards raised to ensure continued adaptability and support for all Australians, with special attention to those with disabilities.

Since 2023, the National Construction Code 2022 (NCC) has required states and territories to apply liveable housing design standards to all new dwellings, reflecting the industry’s commitment to creating safer housing and developments that provide greater access for everyone.

Why compliance matters

Under the NCC, new builds, including any required structural upgrades for existing buildings, must provide clear, step-free pathways for entry and exit. These requirements apply across residential, commercial and public infrastructure projects.

This policy is designed to support people living with disability and older Australians, ensuring safe and accessible entryways and exits to buildings. It also allows for changes over time, such as reduced mobility or the use of walking devices or wheelchairs.

For builders and contractors, meeting these standards can be challenging. Traditional steel, wood or concrete structures require multiple trades, on-site welding or curing, and longer installation times. This increases both cost and complexity, placing pressure on project timelines and budgets.

Plus, when accessibility is not factored in from the start, retrofitting traditional access ramps after construction can be significantly more expensive and disruptive – another reason early compliance is the most practical and cost-effective approach.

Why FRP is the smart choice for access platforms

Luckily, builders and contractors can switch to an innovative solution, Fibre Reinforced Polymer (FRP), and meet the standards – while delivering long-lasting builds that reduce costs and installation times.

Terra Firma’s prefabricated, modular, portable ramps, platforms and stairs are the first of their kind in Australia and are designed to comply with AS 1428.1 standards. Beyond meeting the required standards, an FRP ramp provides a range of benefits that aid accessibility – both for those using them and for those installing them. These include:

- Safety – non-slip surface and fire-resistant material.

- Product prefabricated off-site – we fully engineer and fabricate each ramp for a straightforward, efficient install.

- Faster installation – lightweight (up to 70% lighter than steel), easy to transport and handle (can be cut with handheld tools on-site). The quick installation process and reduced labour lead to significant cost savings.

- Whole-of-life savings – FRP products are resistant to rot, rust, corrosion and UV, meaning they are durable, long-lasting and require minimal maintenance.

- Sustainable – Manufactured from materials that do not require hazardous coatings or preservatives.

How modular access platforms work on-site

Because they are engineered and prefabricated off-site, each modular ramp is supplied ready for straightforward assembly. All profiles are measured, cut, drilled and labelled, with no welding or curing required. Any final adjustments can be made with basic hand tools. This process shortens installation time, reduces disruption on-site and helps projects stay on schedule.

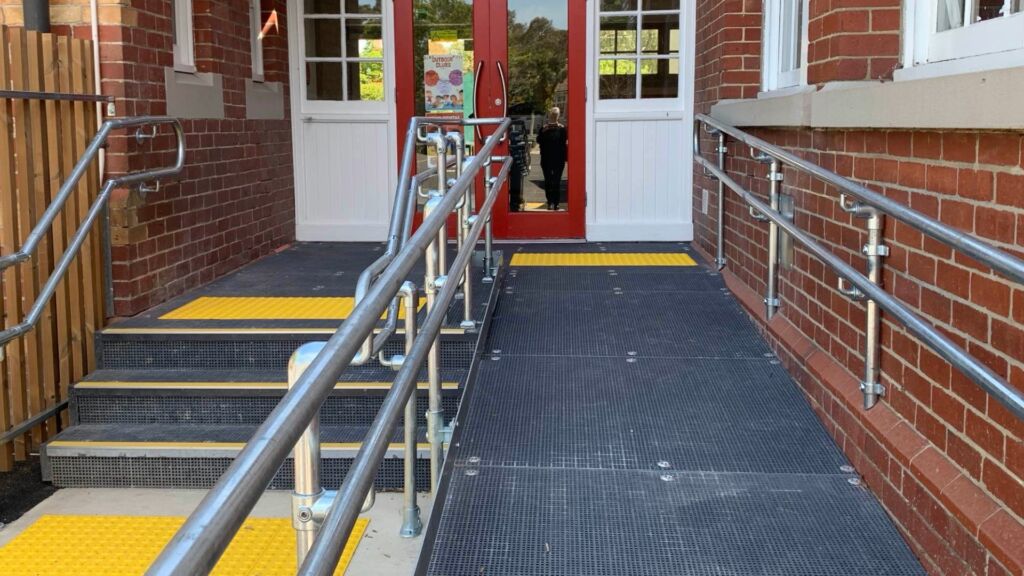

For example, at our access ramp project at a Bayside School, traditional construction methods would have meant extended on-site works, multiple trades and significant disruption to daily operations. The school needed a modular platform and complex ramp configurations that met current standards without impacting learning environments.

Prefabricated FRP ramps, access structures and stairs were manufactured off-site to exact specifications, meeting AS 1428.1 and AS 1657-2018 standards. Installation was completed quickly, reducing labour requirements and keeping the school operational throughout the works. The result was compliant, low-maintenance access ramps that will remain safe and durable for years to come.

This approach is now being replicated at other schools, ensuring each site meets the NCC’s accessibility requirements while benefiting from faster installation and reduced long-term maintenance costs.

FRP structures designed to meet Australian standards

Our prefabricated FRP ramps and modular access platforms are engineered to meet all relevant Australian Standards, ensuring safety, compliance and long-term performance:

- AS 1428.1 – Design for access and mobility

- AS 1657-2018 – Fixed platforms, walkways, stairways and ladders – design, construction and installation, including handrail requirements

- AS 1170 – Structural design actions

- AS 1530 – Methods for fire tests on building materials, components and structures

- Suitable in bushfire zones up to BAL40

By designing to these standards from the outset, we ensure every access platform is compliant, safe and built to last.

Meeting compliance with confidence

An FRP composite structure is the perfect alternative to consider for new building projects and old retrofits for maximum safety and standards compliance. Our Australian-made composites are created by infrastructure and civil works experts, and we can develop FRP ramps for complete accessibility for all projects.

At Terra Firma, we don’t just supply modular ramps – we can also deliver complete, customisable solutions from design to installation that support every stage of your project. Contact us today for expert guidance tailored to your project’s unique requirements.

Share this

Discover the Terra

Firma difference

Learn how we can help support your next project