Water treatment plants (WTPs) and Wastewater Treatment Plants (WWTPs) are vital facilities with highly specific infrastructure requirements. Workers handle liquids and chemicals while accessing treatment tanks from significant heights in all weather conditions. Due to these specific parameters and the need to constantly evolve safety features, the water industry is also embracing the use of newer composite materials.

LC Water (a contractor of Barwon Water) has designed and constructed the infrastructure at the Colac Water Reclamation and Treatment Plant. It has used Terra Firma’s FRP composite sheets for walkways, platforms and other surfaces at multiple WTPs and WWTPs.

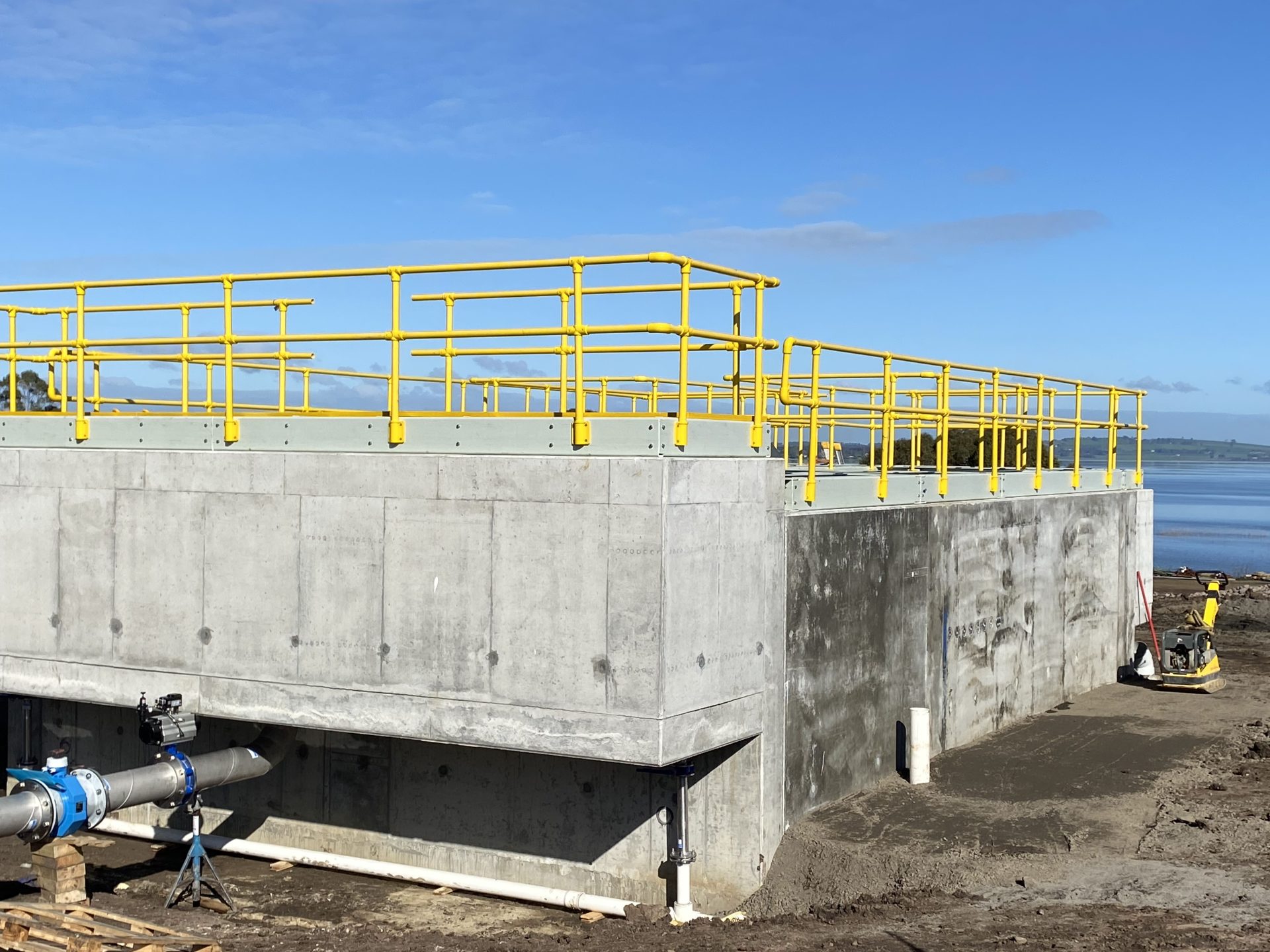

Terra Firma was top of mind when upgrading the Colac Water Reclamation and Treatment Plant. LC Water needed to source a Chemically Enhanced Primary Treatment (CEPT) tank, walkways, stairs, handrails and platforms. After a thorough tender process, they engaged Terra Firma to deliver the project.

The challenge: Working within tight constraints

The upgrade to the WTP included a new CEPT tank – a water storage tank of approximately 3.5 metres in height that workers climb to access the treated water. LC Water needed a lightweight structure that could sit on top of the huge concrete treatment tank without adding significant load to the tank walls. The platform needed to safely allow workers to get on top of the tank and move around with safety-compliant handrail rails the length of the staircase and the access platform.

Terra Firma were engaged to provide them with an FRP platform, connected staircase, top-of-tank walkway and handrails.

With material and labour shortages still significantly impacting the construction industry, reducing the time and cost of projects (including labour and materials) is important to deliver projects on time and within budget.

Ensuring a quick installation while meeting all safety requirements was the key focus for successfully delivering the CEPT tank access project.

The process: Managing specific infrastructure requirements for water treatment plants (WTPs)

The Terra Firma team identified FRP composite materials, pre-fabrication and pre-assembly as key to this project for three reasons:

- Pre-fabrication would allow for the structure to be built off-site, quickly and safely.

- Pre-assembly would cut down on the labour needed to install the fixture on-site.

- The lightweight nature of FRP meant heavy machinery wouldn’t be required for installation, unlike steel, which would have needed significant machinery.

Terra Firma provided comprehensive post-delivery support with detailed assembly guides and in-person support if needed. The Colac Water Treatment Plant team was set up to deliver the upgrade on time and within budget successfully.

Another successful water industry partnership

This bespoke installation delivered:

- Increased employee safety via non-slip materials that withstand all weather conditions

- Chemical-resistant FRP composites

- Reduced load bearing on tank walls

- Reduced installation labour costs

- Easy installation without an industrial crane

Terra Firma’s pre-fabrication and pre-assembly saved LC Water time and money by allowing for a simple on-site connection and assembly process for the staircase and platform and installation without significant heavy industrial machinery.

The Terra Firma delivered the project on time and on budget. The partnership with LC Water was seamless and enjoyable, and Terra Firma looks forward to future water industry collaborations. Get in touch if you want to discuss your project with Terra Firma.

Share this

Discover the Terra

Firma difference

Learn how we can help support your next project