Setting the Standards

This year has been one of steady, meaningful progress at Terra Firma. With your support, we’ve refined how we design, engineer and supply composite solutions, ensuring you have durable, compliant and low-maintenance products that stand up to modern project demands.

Your industry and your requirements continue to shift – and so have we. Our focus this year has been on delivering practical, engineered solutions that reflect the environments you work in and the safety, compliance and cost-efficiency outcomes you’re accountable for.

A key part of this progress has been the continued validation of our engineering and compliance standards. Our products remain designed to meet AS 1428.1 and AS3996 standards, and this year, the updated BTN 033 standard provided renewed certainty for major Victorian infrastructure projects. With our composite pit lids and access covers now reconfirmed under the revised criteria, councils and contractors can specify them directly, confident in their compliance and performance.

Composite solutions for smarter infrastructure

This year we’ve deepened our focus on industries that have started to modernise their infrastructure with composite solutions. From helping councils with lower-maintenance, safer bicycle trails to BESS facilities requiring lightweight, non-conductive trench covers, and dairy farms seeking hygienic, hoof-friendly walkways, we’ve had a busy year.

Our chemically resistant, durable, compliant and low-maintenance composite structures support the long-term safety and reliability of your infrastructure – across a wide range of applications.

Here are a few examples of how our composite solutions were applied across projects in 2025:

- Pit Lids and Access Covers. Terra Firma’s engineered Fibre-Reinforced Polymer (FRP) pit lids were selected by a South Australian Sand Pumping Station to provide safe, corrosion-resistant access in a salt-rich, high-abrasion environment. The lids were custom-designed to match the client’s existing crane setup, enabling crews to complete open and close cycles up to 60% faster.

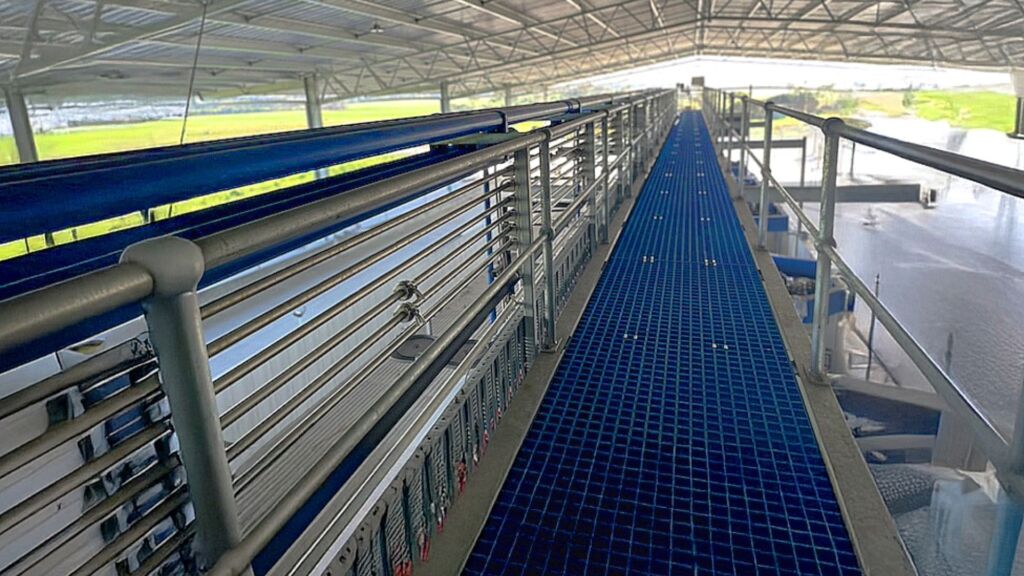

- FRP Grating and Products. FRP walkway grating is increasingly recognised as a practical solution to the challenges faced by farmers like this South Gippsland dairy farm. Unlike traditional materials, FRP is designed to withstand harsh conditions while improving safety and reducing maintenance demands. It combines durability, hygiene and flexibility. Plus, our micro mesh FRP grating helps reduce footing anxiety for animals.

- FRP Utility and Industrial Solutions. A Bendigo water reclamation plant needed to address EPA compliance requirements and improve community amenity. By using our composite access covers, they achieved a high-performance odour containment system that supports operational continuity and environmental goals. The project avoided costly structural rehabilitation while delivering a durable, low-maintenance solution with a long service life.

- FRP Outdoor Access Structures. The Terra Firma Design Team worked with council stakeholders to engineer a safe, compliant and long-life solution to upgrade the timber boardwalk at Queens Park Lake. The new boardwalk helped the council achieve reduced lifecycle costs compared to traditional timber, with ROI analysis showing 30-40% savings over the asset life.

Australia’s civil construction landscape continues to focus on improving safety standards. So, when Niddrie Autistic School needed to install new school ramps, Terra Firma was chosen for our NCC-compliant, easy-to-install solutions.

Together, these projects reflect the growing shift toward safer, lower-maintenance composite infrastructure across a range of environments.

A broader team to meet evolving project demands

To stay aligned with the growing technical demands of your projects, we expanded our team throughout 2025, particularly within engineering. This investment strengthens our ability to respond quickly, provide targeted design support, and ensure each project receives the level of technical guidance required. With deeper in-house capability, we’re better placed to assist with solution selection, technical queries and full-lifecycle project support.

Looking ahead to 2026

As we close out 2025, we’re proud of the improvements made across our products, processes and technical capability.

With a larger engineering team and continued investment in modern composite solutions, we’re well-positioned to support an even broader range of projects next year.

Infrastructure needs will continue to evolve, and we remain committed to delivering safe, durable and cost-effective composite systems that help you meet those expectations.

Thank you for your support throughout 2025. We look forward to working with you in 2026 to deliver stronger, safer and more sustainable infrastructure.

Share this

Discover the Terra

Firma difference

Learn how we can help support your next project